Gochang, South Korea, September 3, 2025

News Summary

Korea Electric Power Corporation has introduced S-CAP, a data-driven software tool that standardizes submarine cable protection by quantifying risk, recommending optimized protection measures and producing design reports. S-CAP accepts site-specific inputs such as anchor types, wave and current conditions, and detailed seabed properties to calculate variable burial depths and recommend alternatives like rock berms or concrete ducts. Backed by numerical modelling and full-scale tests at a large Korean testing centre, the program has received formal document verification and has been applied to a major offshore wind grid link, delivering improved transparency, lower repair risk and cost savings.

Global standardization of submarine cable protection accelerates resilience in offshore grids

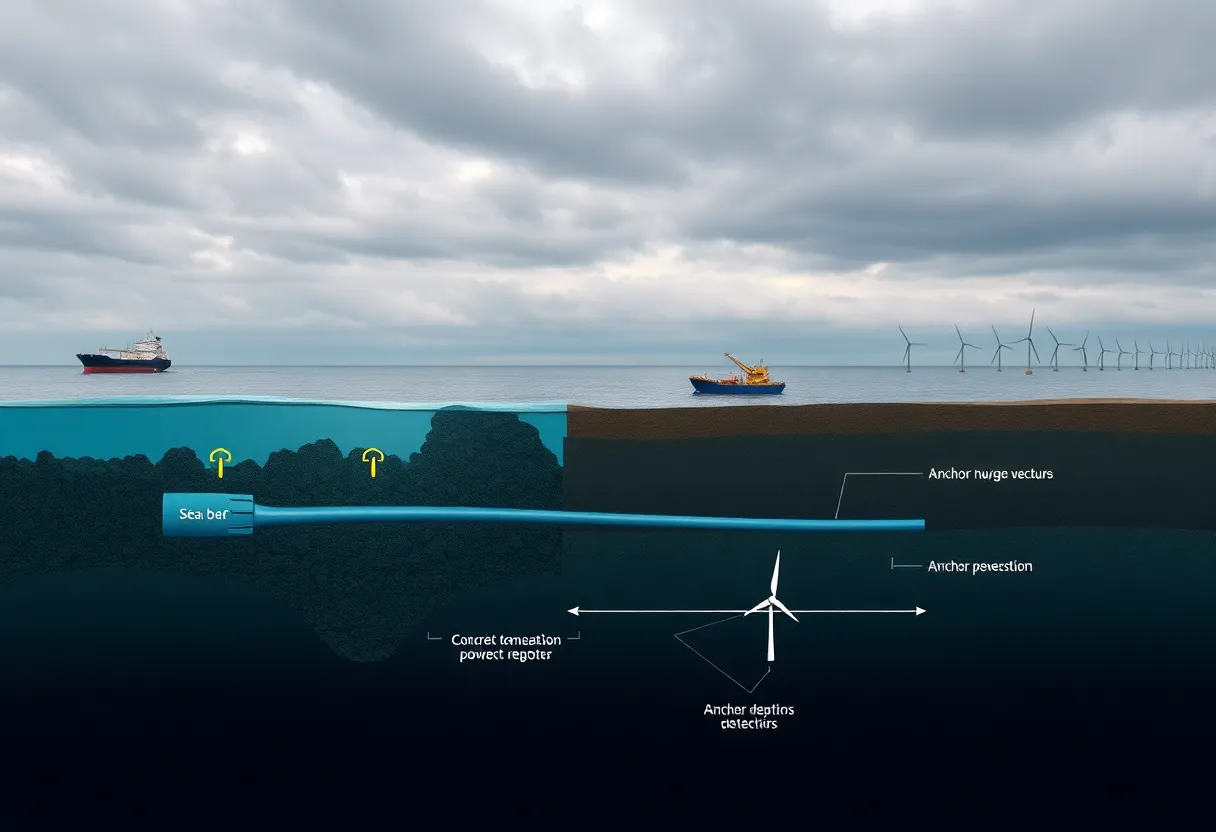

The development of data-driven protection for submarine cables is advancing as part of efforts to accelerate the energy transition and cross-border power interconnections. Submarine cables remain critical links between offshore generators and onshore demand centers, and recent incidents have underscored the high costs of restoration and the importance of safeguarding cables to maintain reliable power supply and avoid widespread outages. Protection strategies must account for marine environment factors such as anchors, currents, wave energy and seabed conditions, making standardized engineering practices a priority for international grid reliability.

Background: why protection matters

- Global demand for submarine cables is rising with climate-mitigating efforts and cross-border power interconnection.

- Submarine cables act as vital arteries in modern grids, linking offshore energy to land-based demand centers.

- Incidents in northern seas and offshore regions have demonstrated the high costs of damage and the risk of large-scale blackouts if protection fails.

- Protection measures must address marine conditions, from dropped anchors to seabed variability and seabed-anchorage dynamics.

Conventional methods and their limits

- Soft seabed scenarios favor burial and trenching, which is the traditional protection method.

- In geologically challenging zones with hard rock or deeper waters where burial is impractical, alternatives such as rock berms and concrete ducts are used.

- Global criteria and protective engineering standards for these alternatives are not uniformly standardized, leading to reliance on empirical or outdated practices.

- Such reliance can yield either overly conservative and costly designs or inadequate protection, increasing the risk of damage and repair costs.

- Determining burial depth remains a critical design issue, with longstanding practice using simplified tools like the Burial Protection Index (BPI) that have limitations for multilayer seabed profiles.

- Legacy approaches often mandated uniform burial depths (for example, fixed minimums such as 1.5 meters) rather than site-specific design.

KEPCO S‑CAP: software, standards, testing

KEPCO Submarine Cable Protector (S‑CAP) is computer software that offers scientifically quantified and optimized protection options for submarine cables. It embeds a set of standards developed to shield cables from a range of marine environmental risks. The software transforms protection from a reactive task into a proactive, data-driven design process. Users input environmental and engineering variables such as anchor types and weights, wave height, current velocity and seabed properties (including unit weight, undrained shear strength and internal friction angle). The program then automatically calculates burial depth for each route segment, proposes multiple protection schemes, and recommends the most appropriate option. It also generates cross-sectional drawings and a comprehensive design report.

The system standardizes and streamlines the protection design process, reducing subjectivity and improving documentation and traceability. KEPCO converted empirical observations into engineering standards and developed chart-based design tools for estimating burial depth under varying anchor types and seabed conditions. It also codified quantified standards for protective structures such as rock berms, including dimensions, materials and installation tolerances, with S‑CAP operating on burial or protective structures as required. By applying variable burial depths tied to localized risk, S‑CAP aims to be more effective and economical than uniform-depth methods.

Testing, empirical design principle and validation

Extensive numerical simulations and full-scale validation tests were conducted at a dedicated testing center with expansive facilities for transmission lines and underground cables, enabling trials under realistic conditions. A key design principle established from testing is that burial depth should exceed the sum of maximum anchor penetration and a safety margin. This empirical finding was converted into formal engineering standards to guide practice.

Validation, applicability and potential savings

Validation progressed with formal recognition in February 2024, when a document verification was issued by a global classification and certification body. The verification highlighted the method as scientifically rigorous, quantitatively based and applicable to real-world submarine cable protection projects. The software is positioned to support global projects across offshore wind connections, HVDC transmission corridors and interregional energy links, and it is applicable to both HVDC and AC submarine cables. In practical terms, the method is expected to reduce construction costs by around 5%, roughly USD 2 million per 100 kilometers of cable, according to the cited estimates.

Practical implementation: project outcomes

The software was applied to a major wind-to-land connection project along the Korean southwest coast, with grid integration targeted by 2029 and full completion by 2031. Deployment of S‑CAP on this project led to a reduction of cable installation costs by an estimated 50%, about USD 3.6 million, while also reducing environmental impact. The digitized reporting format and transparent design logic helped strengthen trust between project owners and contractors, illustrating how data-driven methods can support collaboration and accountability in complex offshore builds.

Risk reduction and broader benefits

Preventing cable damage before it occurs strengthens structural integrity and durability of submarine conduits, reducing the risk of outages and costly repairs. A standardized, data-driven design method supports stable electricity transmission to vulnerable or remote regions, including island communities, in high-risk environments. The approach integrates field-tested methodologies with globally recognized design principles to deliver a holistic protection strategy.

LS Cable & System, JAKO project and regional connectivity needs

A consortium is pursuing a turnkey undersea telecommunications link of about 260 km between Busan, South Korea, and Fukuoka, Japan. The Busan–Fukuoka project is set to be completed by 2027 and is described as LS Cable & System’s first international submarine cable contract of this scale. The JAKO cable will strengthen connectivity to support mounting demands of AI workloads and cloud services in Northeast Asia, aiming to accommodate rising data traffic driven by major cloud providers. LS Cable & System, established in 1962, is a global manufacturer offering design, engineering and installation services for HVDC systems, renewable-energy cables and submarine telecom cables, and it plans to oversee the full EPC process to deliver a future-proof link between the two nations. The JAKO cable is positioned as a strategic response to growing regional infrastructure needs amid expanding economic and geopolitical ties across Asia.

E2A subsea cable: a trans-Pacific, high-capacity link

Construction has begun on a new subsea cable connecting East Asia and the United States. The E2A cable is planned to run about 12,500 km and will land at Toucheng in Taiwan, Busan in South Korea, Maruyama in Japan and Morro Bay, California. Built by a major subsea systems supplier, the E2A line will support more than 192 terabits per second across 12 fiber pairs and will employ 18 kV power technology. The project is set to go live in the second half of 2028. The consortium includes SoftBank, SK Broadband, Chunghwa Telecom and Verizon, with SoftBank providing the Maruyama landing station. In the broader context, other recent initiatives include plans to invest in subsea routes between the US and Japan, illustrating growing momentum for robust, cross‑regional data infrastructure to support AI, cloud and digital services. The E2A project is designed to complement other cables linking the US West Coast to Northeast Asia, reflecting a broader push to diversify routes and capacity across the Pacific corridor.

These developments reflect a trend toward formalizing submarine cable protection through standards, validated methods and transparent reporting. They also highlight the evolving role of cable systems in supporting high-capacity, low-latency connectivity for offshore energy integrations, AI workloads and global data flows.

FAQ

What is KEPCO S‑CAP?

The KEPCO Submarine Cable Protector is a software tool that provides quantified, standardized design options for protecting submarine cables. It integrates environmental inputs, generates burial depths, suggests protection schemes, and outputs design reports to support a data‑driven approach to cable protection.

How does KEPCO S‑CAP work?

Users input environmental and engineering variables such as anchor types and weights, wave height, current velocity and seabed properties. The software then calculates optimal burial depth for each route segment, offers multiple protection options, and produces design drawings and a comprehensive report.

What are the potential benefits of using S‑CAP?

Benefits include standardized design practices, reduced subjectivity, improved documentation, potential cost reductions, and better alignment of burial and protective structures with localized marine risk profiles.

Where is S‑CAP applicable?

It is applicable to both HVDC and alternating-current submarine cable projects and is intended for offshore wind connections, HVDC transmission corridors and interregional energy links.

What other projects are associated with these developments?

Related initiatives include a Busan–Fukuoka undersea telecom link being developed on a turnkey basis and the E2A subsea cable connecting East Asia with the United States, featuring high capacity and multi‑landing points.

Key features of the post

| Feature | Description |

|---|---|

| Subject | Advances in submarine cable protection design and its application to major offshore and interregional cable projects |

| Software | S‑CAP provides quantified burial depths, multiple protection options and documentation outputs based on localized marine risk data |

| Standards and validation | Engineering standards embedded in the tool; formal verification by a major certification body in 2024; applicable to HVDC and AC systems |

| Key outputs | Optimal burial depths, protection recommendations (burial, rock berms, etc.), cross‑sectional drawings and design reports |

| Supported projects | South Korea’s offshore wind connections, Busan–Fukuoka undersea link, JAKO telecom cable, and East Asia–U.S. E2A cable |

| Cost and risk impact | Potential reductions in installation costs and environmental impact; improved reliability and project transparency |

Deeper Dive: News & Info About This Topic

Additional Resources

- Korea JoongAng Daily: LS Cable wins $115M submarine cable order from Taiwan

- Wikipedia: LS Cable & System

- Capacity Media: LS Cable joins Korea–Japan submarine cable project

- Google Search: Korea Japan submarine cable Busan Fukuoka

- Financial Times: Subsea cable / industry coverage

- Google Scholar: submarine cable protection anchor penetration

- DataCenter Dynamics: Construction begins on E2A subsea cable connecting US to Asia

- Encyclopedia Britannica: E2A subsea cable

- Inspenet: Taihan secures subsea cable contract for Korea offshore wind project

- Google News: Taihan subsea cable Korea offshore wind